Technology

Great Northern Salmon is a frontrunner in low CO2 footprint (life cycle CO2 emissions Kg CO2/kg product). We employ 100% renewable power, carbon-negative pyrolysis technology, and avoid long transport by delivering to local/regional markets.

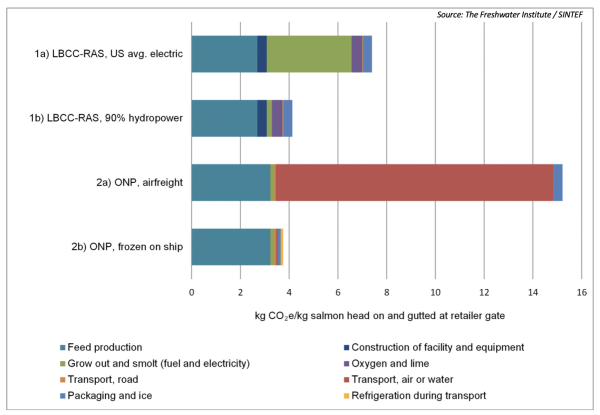

CO2 – Approximately 4 kilograms of CO2 per kilo product compared to 14 + kilograms of CO2 for net pen imports and up to 60 kilograms of CO2 for domestic red meat. Carbon-free power, avoidance of airfreight, fishmeal-free fish feed, and local/regional market are the most important factors reducing CO2 emissions in the Katahdin Salmon case. No other 100% renewable power case exists.

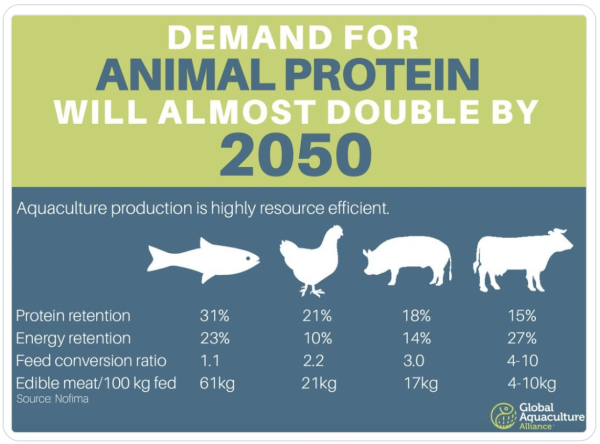

1:1.1 feed conversion ratio (FCR) in RAS – the feed factor for salmon is more efficient than any other animal protein we buy in the store. In 2023, the first feed without fish meal will be commercially available at volumes and will be the target feed for Great Northern Salmon.

Climate change resilient – with temperature control, water quality control in a contained system, and limited water use, Great Northern Salmon is climate change resilient.

Pyrolysis technology is capable of processing all waste streams into carbon char with an economic value. The process is carbon-negative and qualifies for carbon credits.